BALAJI PLASMA CNC CUTTING MACHINES, SATARA

Balaji Plasma Cutting Machines has been established in 2021 as a CNC Machines and equipment's manufacturing company in Satara, Maharashtra part of west-central India.

Introduction

Balaji CNC cutting machines is an industry-leading manufacturer and supplier of CNC Plasma Cutting Machine, CNC Oxy Fuel Cutting Machine, CNC Flame Cutting Machine, Portable Plasma Cutting Machine, CNC Plasma Cutter, Plasma Cutting Machine, CNC Plasma Controller, CNC Gas Cutting Machine, CNC Metal Cutting Machine, Plasma Laser Cutting Machine, Plasma CNC Machine, CNC Plate Cutting Machine and Gantry Type CNC Plasma Cutting Machine.

Our assorted collection of CNC cutting machines delivers the solutions for a wide variety of customers and an application, helping you maximizes performance and profits.

Leading Manufacturer of CNC Plasma & Oxy Fuel Cutting Machine

We are a prime manufacturer, supplier, exporter and trader of CNC Plasma Cutting Machine, CNC Oxy Fuel Cutting Machine, CNC Flame Cutting Machine, Portable Plasma Cutting Machine, CNC Plasma Cutter, Plasma Cutting Machine, CNC Plasma Controller, CNC Gas Cutting Machine, CNC Metal Cutting Machine, Plasma Laser Cutting Machine, Plasma CNC Machine, CNC Plate Cutting Machine and Gantry Type CNC Plasma Cutting Machine.

Our products are highly appreciated for their durability, low maintenance, performance and affordable prices. Owing to the quality of our range, we are able to meet the growing demands of heavy engineering industries, fabrication units, and refineries.

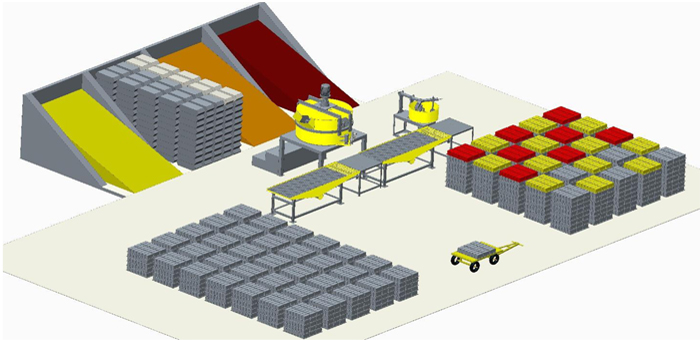

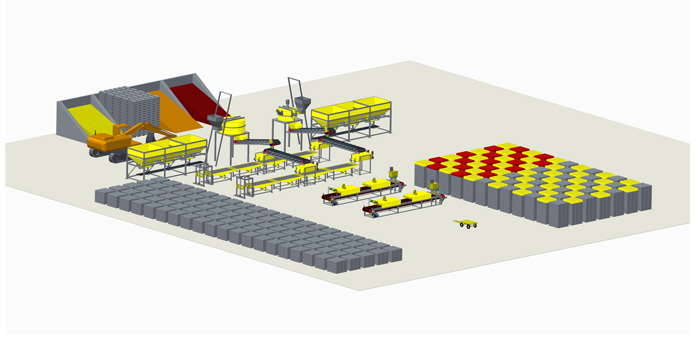

Our Products & Services

Our products are regarded for their premium quality, sturdy construction and cost-effective operation. We constantly strive to maintain the quality of our products. Our products are widely used in construction, heavy engineering plant and refinery requirements.

We have built a highly sophisticated infrastructure base. This infrastructure includes manufacturing, research and control, sales and many other departments. We use the latest machines and processes in our production, quality assurance and packaging. In addition, our R&D unit works dedicatedly in exploring the latest technologies in design as well as rectifying the deficiencies in the products manufactured by us.

Owing to our ethical business policies, transparent dealings and customer-centric approach, we have a long list of our satisfied clients. As an exporter, supplying products to various locations across the globe, we are committed to the total quality assurance of our products and services. Our products are manufactured using highly developed technology.

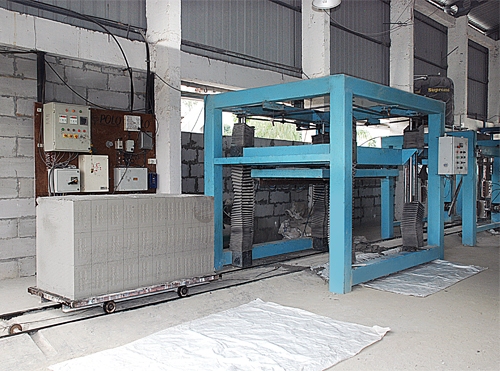

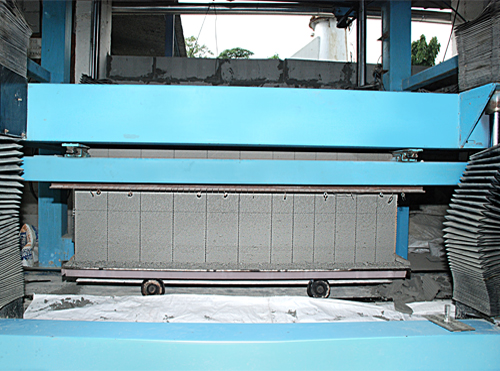

Our Infrastructure

We have continuously developed and upgraded our infrastructure facility to meet all kinds of requirements of the clients. Spread over a large area, our infrastructure consists of separate departments for each operation such as production unit, warehouse, R&D, quality testing and servicing. It helps in increasing productivity, operational and cost efficiency.

The state-of-the-art manufacturing unit we have developed is set up with all the required machines and equipment to enable us to manufacture the range. Our latest machinery has enabled us to produce best quality products in a very short span of time.