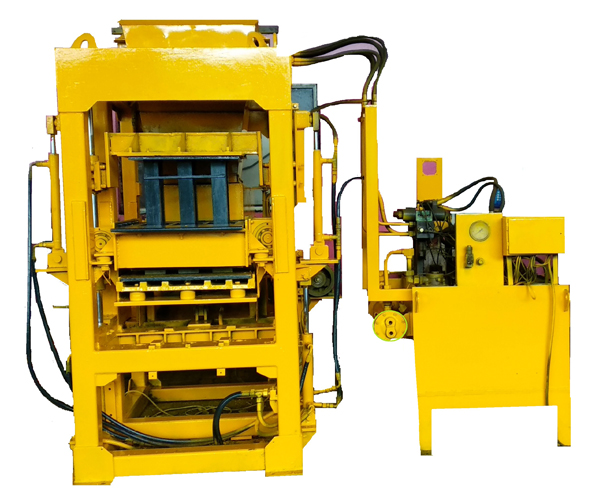

Concrete Block Machine | Balaji Construction Machines and Spares, Satara

Capacity: 4000 Blocks/11000 Pavers

Beneficial Points:

- Vibration Technology

This machine has direct mould vibration technology, which gives you the best synchronized vibration PLC control with hydraulics and electrical, mould vibration technology is better than pallet vibration.

- Multi Product Machine

This machine manufactures concrete blocks, bricks, uni pavers, colour layer pavers with vibro compaction technology (this product is commonly used for government project).

- Material Feeder

Individual material feed box is provided for both back layer and top layer.

- Mould Life

Material for mould is HCHCR D2 having 55 HRC hardness gives 4,00,000 cycles mould of life.

- Pallet feeding and collecting system

This machine has an automatic pallet feeding and ejection system controlled by PLC. Pallet stacking machines are also supplied in this plant.

- Electricity Consumption

High quality electronics components, motors, vibrators and high efficiency gearboxes will consume less power for production.

- Minimum labour required

Fully auto and manual controls are designed to operate by semi-skilled workers. Only 2 skilled and 4 unskilled labours are required in fully automized plant.

Product Name | Cavity | Cycles / minutes | Production Capacity |

Fly ash bricks 9 x 4 x 3 | 6 | 6 | 19200 bricks / shift |

| Colour Pavers | 6 | 6 | 15000 pavers / shift |

| Uni Pavers | 6 | 6 | 19200 uni pavers / shift |

| Concrete Blocks | 3 | 5 | 7200 blocks / shift |

No comments:

Post a Comment