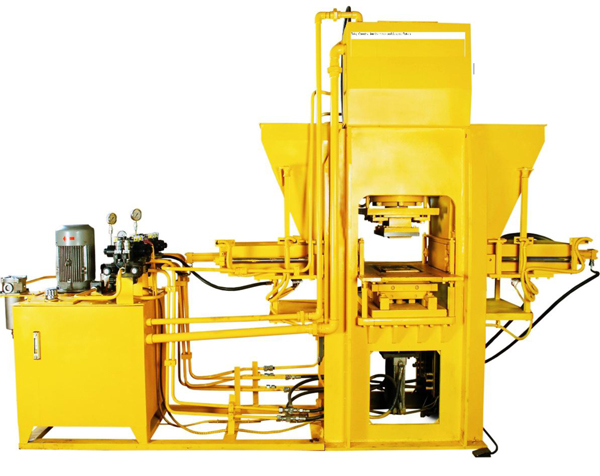

Colour Paver Making Machine | Balaji Construction Machines and Spares, Satara

Fly Ash Bricks- Colour Paver Making Machine- 7500 Pavers/Bricks

Beneficial Points:

- No Pallet Cost

No pallets required for production or transportation of products. Approximately recurring cost of 1000 pallets will be saved per year. Manpower cost for pallet handling also save.

- Multi Product Machine

This machine can manufacture bricks, uni pavers, colour layer pavers, interlocking blocks. This is best machines for startup plants for manufacturing variety of products.

- Cycle Time

10 seconds for 1 stroke which is fast in class.

- Mould Life

Material for mould is HCHCR D2 having 55 HRC hardness gives 2,50,000 cycles / 5,00,000 bricks mould of life.

- Height Maintain Blocks

No separate mould required for 4-inch or 3-inch height. Bricks height can be maintained by using height maintain blocks.

- Electricity Consumption

0.015-unit electricity consumption per brick. Comparatively 2 times less than vibro press machine.

- Minimum Labour Required

Fully auto and manual controls are designed to operate by semi-skilled workers. 1 skilled and 5 unskilled labours can manufacture 6700 bricks in a shift.

| Product Name | Cavity | Cycles / minutes | Production Capacity |

|---|---|---|---|

Fly ash bricks 9 x 4 x 4 / 3 | 2 | 7 | 6700 bricks / shift |

Colour Pavers | 2 | 5 | 4800 Pavers / shift |

Interlocking Blocks | 2 | 5 | 2400 blocks / shift |

Uni pavers | 2 | 7 | 6700 blocks / shift |

- Energy Transmission: Hydraulic compaction

- Energy source: Electrical, 3 phase, 440 volts

- Electronics control: PLC base fully automatic

- Motor: 10 HP SIMENS make

- Hydraulic pressure: 63 Tonnes

- Vibrator: NIL

- Hydraulic oil tan: 300 Liters

- Cycle time: 7.5 seconds

- Stroke per minute: 8 Stroke

- Cooling: Condenser type cooling

- Number of pallets: Not required

- Material Feeder: Individual material feed box

- Total labour required: 1 Skilled & 4 Unskilled labours

No comments:

Post a Comment